Vintage MG Parts - Parts Site for the MMM Enthusiast

Engine Oil Pump - C, D, J1, J2, J3, F Type and J4

(click on image to enlarge, click again to close)

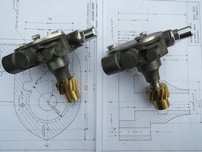

Undoubtedly one of the rarest parts to source for the C, D, F and J engine and a part which has not been remanufactured for at least 10 years. We have produced our own patterns, we have our own independant gear cutting suppliers using state of the art gear cutting technology and we have achieved our objective to produce a 'spot the difference' product when comparing with the original factory pump. We are the sole manufacturer / supplier of complete J Type oil pumps.

About Vintage MG Parts Oil Pumps

- The first reproduction pump to incorporate all original external casting profiles including cross-drilled oil way bosses and cored oil reception and exit ports within the lower gear chamber areas

- The oil pump body is cast from high density SG iron

- Cross-drilled oil bypass galleries

- Precision CNC machined gear chamber incorporating 1000th inch clearance to the tips of the teeth and 2000th inch end float

- Gears produced on a state of the art brand new £0.5M CNC gear cutting machine with teeth profiles of ground-like (as opposed to hobbed) finish. This is a new standard for MMM oil pump gears.

- The oil pump pinion gear is machined from EN32

- The idler is a hardened steel precision ground and polished dowel pin

- The pressure relief piston has been precision ground and heat treated

- The oil pressure relief spring is custom made to the original factory specification and with ground ends

- Original thread forms within the housing

- The spring housing is to the original profile and clear zinc plated

- We are using a 4.00mm thickness gear cover plate in stainless steel

- Stainless steel cover plate screws and washers

- VMGP oil pump spare components are all interchangeable with factory original parts

___

___

(click on image to enlarge, click again to close)

Some Background History to the F/D/J Type Oil Pump

The F type oil pump was a development of the pre-war OHC Morris Minor engine which was similar in many characteristics, the earlier pump incorporating 1/4 inch deep gears and the oil delivery bore within the pump was limited to 5/16 inch diameter.

The M Type pump incorporated larger gears to assist oil flow capacity with a depth of 5/16 inch, otherwise these were the same as the OHC Morris Minor oil pump.

A larger capacity oil pump with a modified body to include cross-drilled oil ways and deeper gears at 9/16 inch was produced for the F Type and was then also fitted to the production D and J2 types. In addition, the oil way intake had its bore diameter increased to 3/8 inch diameter.

This third generation pump was then also fitted to the C and J4 although the pinion gear was increased in length to accommodate the extra depth in the front housing which was needed to take the water pump. We now offer both the standard C/D/J2 and J4 oil pump gear sets.

On assembly, we run each pump up to 1,200 rpm with full oil circulation.

Having produced an initial couple of batches that have all sold, we have completed the majority of machining operations on the body and lid components and so we are generally able to finish machine and assemble within a circa 10 day turnaround.

Price £POA--Complete J2 oil pump

Price £POA--Complete C/J4 oil pump

Price £_80.00--J2 oil pump gear set (pair)

Price £_80.00--C/J4 oil pump gear set (pair)

Price £_PP --Drive gear (ready for roll pin drilling)

Price £__1.25--Woodruff key for drive gear/oil pump drive gear

Price £__0.35--1/8 inch diameter roll pin for drive gear

Price £_20.00--Pressure relief spring housing

Price £__5.50--Pressure relief spring

Price £__0.50--Pressure relief spring housing fibre washer

Price £_19.00--Pressure relief piston

Price £__3.00--Idler pin

Price £_10.00--Oil pump lid (4mm stainless steel)

A note to customers fitting new oil pump gears to original pump body castings: it is essential that the customer checks that the pump is assembled with the correct end float. This must not be less than 2000th inch as otherwise the pump will be restricted and will cause the bronze crank/distributor drive gear to fail. End float can be determined through varying the thickness choice of gasket between the body and the lid.