Click here to visit our website

Welcome

to our latest Newsletter

What's been happening recently ...

During the latter part of 2012, we were ‘out of circulation’ for a few months. We are now back up to speed with MMM parts manufacture, enjoying a new workshop, new machines and some new products which are either announced in this Newsletter or will be announced on the website in the near future. The website will also be brought up to date shortly, although some of you will have noticed that we have been continually adding to our Visitor’s Gallery and updating some photographs where restoration has progressed.

We recognised a couple of years ago that we were quickly running out of workshop and storage space and actual machining time was becoming generally more inefficient to the point that we could not turn around parts as effectively as we would have liked. We were also becoming increasingly frustrated with the operating limitations of our machines so things had to change.

So, we moved home and business in August last year when we were incredibly fortunate to find a local farmhouse with a large workshop and outbuildings that were ideal for expanding the manufacturing side of our business. It took several months however, to relocate the workshop and with the kind assistance of a local farmer, we had our old and new machines lifted into position ready to start clearing the backlog of orders. Happily, we are now operating at full speed again and with a new level of efficiency.

We would like to thank our customers for their patience during this upheaval and for the kind words of support we received. We would like to add that we hope never to undergo this moving experience in the foreseeable future or indeed in our lifetime!

What's new ...

R Type Style Blow-off Valve: The supply of blow-off valves had, for us, become far too sporadic and unreliable as this was not an in-house product. Consequently, we decided to make our own product with an original design which, up until now, has not been readily available. We therefore made our own patterns to produce the original R Type style blow-off valve. These are different from the modern alternative in that the main body section is a little shorter with the neck being slightly longer. The diamond outlet flange is also smaller than the typical modern repro valve. We now incorporate the original ‘BA’ casting letters on the body and we also core out the casting void area as opposed to machining out the centre of the casting which allows us to incorporate a spring top location point around the valve stem hole. We have our own springs custom made and can set the release pressure for individual customer requirement, ranging from 10 lbs to 22 lbs boost.

Due to complacent standards in the manufacturing of some inlet manifolds available, the hole centres on the manifold valve platforms have been found to vary which is not helpful! So, for the first time, enthusiasts can specify their centre distance preferences and we can accommodate 2 3/8th, 2 1/2 and 2 5/16th inch centre distances. We can also drill holes to 1/4 or 5/16th inch diameter as appropriate.

A further difference is that instead of the modern repro having the spring heat shield cup machined from steel round bar, we have had these metal spun in brass, again just like the originals. We are aware of two alternative repro sources where these are being incorrectly installed upside down, so don’t be surprised when you see our heat shield sitting on a machined spigot on the top side of the valve head. This problem was recognised in the 1930’s by the MG factory whereby enthusiasts were disassembling the valve and not really understanding the purpose of the bell cup and these invariably ended up then sitting on the top of the spring. The cup is a heat shield designed to protect the spring from losing tension through heat contact when the valve trips and has an out-turned rim that helps dissipate any hot gases. Click here for a link to the original MG Factory Service Sheet.

Unlike the previous repros we stocked, we drill and tap the outlet flange on our own blow-off valves as per the original design for those who wish to mount a blast deflation plate. This provides useful protection for the ears if tinkering under the bonnet should the engine spit back.

This product is made in-house by Vintage MG Parts and is cast in LM6 for a strength and high shine retaining quality.

Engine

Water

Jacket Plates, now for the F Type and Wolseley: Over

the past couple of years, enthusiasts have continued to place

requests for us to cater for the F type. We can now announce the F

Type

water jacket using VMGP tooling. Being the first company to produce

stainless steel water jackets and the only manufacturer to use 1.3 mm

thickness plate, we have made these plates in the same material. We

have also invested in tooling to produce nitrile

gaskets for the F type and in addition, for all F, P and L/K/N

jackets, we now supply the diamond gasket for the water inlet

manifold. All gaskets are made to exacting engine block profiles with

no rubber over-spill and all screw holes in our gaskets are undersize

for water sealing. The plates have a satin finish so you can either

polish up or apply acid etch before finishing with engine enamel.

Engine

Water

Jacket Plates, now for the F Type and Wolseley: Over

the past couple of years, enthusiasts have continued to place

requests for us to cater for the F type. We can now announce the F

Type

water jacket using VMGP tooling. Being the first company to produce

stainless steel water jackets and the only manufacturer to use 1.3 mm

thickness plate, we have made these plates in the same material. We

have also invested in tooling to produce nitrile

gaskets for the F type and in addition, for all F, P and L/K/N

jackets, we now supply the diamond gasket for the water inlet

manifold. All gaskets are made to exacting engine block profiles with

no rubber over-spill and all screw holes in our gaskets are undersize

for water sealing. The plates have a satin finish so you can either

polish up or apply acid etch before finishing with engine enamel.

Gearbox

Layshaft Roller Bearings:

Caged needle roller bearings appeared a few months ago on the MMM

Forum. These

were available in limited supply only and at £75 for a set of three and

sold immediately. A good MMM friend has brought a

completely brand new source of high quality roller bearings to our

attention. These are exactly correct for what we need in our gearboxes

and are available from VMGP at a significant discount.

Gearbox

Layshaft Roller Bearings:

Caged needle roller bearings appeared a few months ago on the MMM

Forum. These

were available in limited supply only and at £75 for a set of three and

sold immediately. A good MMM friend has brought a

completely brand new source of high quality roller bearings to our

attention. These are exactly correct for what we need in our gearboxes

and are available from VMGP at a significant discount.

KI-GASS

Jets for Supercharging: These are now in stock. Up until now,

these have

generally been hard to source for MMM cars and recently a pair of jets,

a

T-piece and 90 degree elbow with fittings, set one of our MMM

customers back £100 for the dual set. The Vintage MG Parts price will

be £68 for the current batch we have in stock. We have designed our

own Ki-gass jet heads and also sourced and reprofiled our 1/8th BSP 90

degree and

T-piece

brass fittings. We can supply a complete dual jet assembly including

copper washers, or individual components. We can also supply 1/8th inch

OD

copper tubing to your desired length.

KI-GASS

Jets for Supercharging: These are now in stock. Up until now,

these have

generally been hard to source for MMM cars and recently a pair of jets,

a

T-piece and 90 degree elbow with fittings, set one of our MMM

customers back £100 for the dual set. The Vintage MG Parts price will

be £68 for the current batch we have in stock. We have designed our

own Ki-gass jet heads and also sourced and reprofiled our 1/8th BSP 90

degree and

T-piece

brass fittings. We can supply a complete dual jet assembly including

copper washers, or individual components. We can also supply 1/8th inch

OD

copper tubing to your desired length.

‘Jackson’

Design Supercharger Inlet Manifolds for J and P Types: Shiny

MG

crested aluminum inlet manifolds can look pretty on a MMM car but Reg

Jackson in the 1930’s recognised their limitations. Having a single

plenum, the gas charging in at one end to find it’s way to the ports,

the oiling up of certain spark plugs and uneven gas

pressure to each cylinder, being all too common. These manifolds

were

never

therefore, particularly efficient at certain ranges of pressure. The

Jackson manifold was developed to

overcome all these problems and it worked.

‘Jackson’

Design Supercharger Inlet Manifolds for J and P Types: Shiny

MG

crested aluminum inlet manifolds can look pretty on a MMM car but Reg

Jackson in the 1930’s recognised their limitations. Having a single

plenum, the gas charging in at one end to find it’s way to the ports,

the oiling up of certain spark plugs and uneven gas

pressure to each cylinder, being all too common. These manifolds

were

never

therefore, particularly efficient at certain ranges of pressure. The

Jackson manifold was developed to

overcome all these problems and it worked.

We now have a fabricator working for us to produce our own manifolds. For the J Type manifold as with our own J4 rep, we have chosen to have the gas entering the manifold from the underside and at a central position so gas distribution is balanced to all cylinders. To us, this seemed to be a logical common sense approach and we know from our own car that it works very well indeed. We can however, also produce the more standard design where the gas enters the manifold from the front. For our preferred design, the path for gas traveling from the blower to the manifold only has two as opposed to four bends when navigating the induction pipe from the blower to the plenum, so another reason to chose your manifold carefully.

We are using a slightly thicker than standard repro manifold pipe wall thickness and our manifolds are expertly jigged up and bronze welded. These are not the TIG welded MMM type. We have also positioned our Ki-gass nozzle entry points in a more sensible position to those we have studied, where the dual Ki-gass injectors often sit either side of the blow-off valve which makes for a messy connection between the two. We therefore mount the Ki-gass jets on the two link pipes between the plenum and emulsion tube which we feel also provides a preferable position for better starting and even the atomizing of fuel into each port.

The manifolds are either in stock or made to order and supplied in a hycote, powder coated or vapour blasted bare steel finish.

MMM Engine

Sump Oil

Strainers (J, F/P/L and N types): With

several problems being

reported

on misalignment issues for new sump strainers, we decided that we

should start making these. Apart from relying on

our local CNC machinists to turn up our hex nuts, we produce these

in-house. We use fine brass 40 grade brass cloth, correct pattern

perforated

tubing and thick wall 16 gauge copper piping. The whole part is then

neatly soldered together. Please note that for customers using our deep

capacity L/K sumps,

we use the longer N Type strainer.

MMM Engine

Sump Oil

Strainers (J, F/P/L and N types): With

several problems being

reported

on misalignment issues for new sump strainers, we decided that we

should start making these. Apart from relying on

our local CNC machinists to turn up our hex nuts, we produce these

in-house. We use fine brass 40 grade brass cloth, correct pattern

perforated

tubing and thick wall 16 gauge copper piping. The whole part is then

neatly soldered together. Please note that for customers using our deep

capacity L/K sumps,

we use the longer N Type strainer.

Several enthusiasts who initially suggested we should make this part also asked that we increase the thickness of the hex head up from 3/16th inch. Many of us have struggled in the past to find a spanner which is large enough for the job and when it does fit, it invariably slips off, chewing up the hex head in the process. Well, we have taken these comments on board and decided to come up with a logical approach to help all enthusiasts and not just those who purchase the VMGP sump strainer. Please read on...

The MMM Sump

Oil Strainer Spanner: Here

it is, the Vintage MG Parts ring spanner for J Types and the larger

F/L/K/P/N Types. Snug fitting, this addresses all problems and

hopefully will be

the end of finding that elusive spanner and chewed up hex heads. The

VMGP ring spanner is offered as a

free gift

with all our sump

strainer products or can be purchased separately. Please

remember to quote "J Type" or any other model as there are two sizes.

The MMM Sump

Oil Strainer Spanner: Here

it is, the Vintage MG Parts ring spanner for J Types and the larger

F/L/K/P/N Types. Snug fitting, this addresses all problems and

hopefully will be

the end of finding that elusive spanner and chewed up hex heads. The

VMGP ring spanner is offered as a

free gift

with all our sump

strainer products or can be purchased separately. Please

remember to quote "J Type" or any other model as there are two sizes.

Lucas Style

Triangular Mirror Brackets: Having previously manufactured the

D/J1/F1/F3/L1 drivers side mirror brackets, we are currently running

another batch of this

rare part.

Lucas Style

Triangular Mirror Brackets: Having previously manufactured the

D/J1/F1/F3/L1 drivers side mirror brackets, we are currently running

another batch of this

rare part.

Rarer still, is the J4 Lucas triangular 160 type side mirror bracket which has never before been commercially available. We have spent the last few weeks carefully machining and assembling this new part and by the time you read this newsletter, they should hopefully have been returned from our chromers. What is the difference between the two types of bracket? Well, the J4 bracket is somewhat taller for providing enough extension to clear the windscreen B-nut.

No J4 or J4 replica is complete without this part and it is also a rather nicer alternative to the standard MMM single stem mirror arm. We are only making a one-off batch of these for 2013 and once they are gone, they are gone!

MG Crested P

& N Type Oil Filler Securing Nut for the Rocker Box: Several

customers have emailed this requirement through to us over recent years

as it has not been reproduced and we have finally got around to

manufacturing them. They comprise a fully machined and chromed brass

casting.

MG Crested P

& N Type Oil Filler Securing Nut for the Rocker Box: Several

customers have emailed this requirement through to us over recent years

as it has not been reproduced and we have finally got around to

manufacturing them. They comprise a fully machined and chromed brass

casting.

Some new parts introduced since the last newsletter ...

L/K and N Type VMGP Sumps: Having finished the prototype around six months ago, all the first batch sold immediately. We were very pleased with how they turned out although during our property move, the pattern maker decided to make good use of his rest time and incorporate some minor tweaks to the pattern. It did mean stripping the pattern down however! We have some more sump orders and so are about to run another batch shortly and we can accommodate more orders on top. Please register interest in the usual way through our webpage or click here or click image to visit our website for more information.

Both our N Type and L/K sumps are exclusive to Vintage MG Parts and again, if ordering the deeper L/K sump, we use the larger N Type strainer.

Vertical

Oil Drain Galleries and Seals plus Differential Dipstick and Holder

Components: Following the very successful

introduction of these

parts, we are now manufacturing further batches. Click here or click image to visit our website for

more

information.

Vertical

Oil Drain Galleries and Seals plus Differential Dipstick and Holder

Components: Following the very successful

introduction of these

parts, we are now manufacturing further batches. Click here or click image to visit our website for

more

information.

P Type

Exhaust Manifold: This

was a

product featured as being in production during our last Newsletter

release. It has proved to be a worthwhile product to re-manufacture and

surprisingly, has on several occasions been ordered as a replacement

product for other manifold reproductions. It demonstrates just how

particular our MMM community are in having correct re-manufactured

parts fitted on their cars. We no longer supply the cheapest price

for the P type manifold due to a price drop elsewhere but we are

retailing an entirely different VMGP product. Click here or click image to visit our website for

more

information.

P Type

Exhaust Manifold: This

was a

product featured as being in production during our last Newsletter

release. It has proved to be a worthwhile product to re-manufacture and

surprisingly, has on several occasions been ordered as a replacement

product for other manifold reproductions. It demonstrates just how

particular our MMM community are in having correct re-manufactured

parts fitted on their cars. We no longer supply the cheapest price

for the P type manifold due to a price drop elsewhere but we are

retailing an entirely different VMGP product. Click here or click image to visit our website for

more

information.

See our Latest New Parts section on the website for updates of new parts and new stock. In addition to the new parts listed earlier, we have other unpublicised projects we are currently working on and these will periodically appear on the Vintage MG Parts website.

New stock/major part re-runs ...

D43 dashlamps

are again in production for the P & N Types as well as the K types

and

we will have assembled these by the time this Newsletter is released. Click

here or click image to visit our website for more information.

D43 dashlamps

are again in production for the P & N Types as well as the K types

and

we will have assembled these by the time this Newsletter is released. Click

here or click image to visit our website for more information.

P Type sumps are once again in stock

to go with our sump oil strainers. Click

here or click image to visit our website for more information.

We

have almost finished making

another small batch of 10 only, early

stepped

two piece Dogbone filler caps for the J and P Types.

This will be our only batch available this year as it is such a time

consuming component to manufacture. The cap is supplied complete with

spring loaded brass metal spun internals. Click here or click image to visit our website for

more

information.

We

have almost finished making

another small batch of 10 only, early

stepped

two piece Dogbone filler caps for the J and P Types.

This will be our only batch available this year as it is such a time

consuming component to manufacture. The cap is supplied complete with

spring loaded brass metal spun internals. Click here or click image to visit our website for

more

information.

Finally,

we have replenished our supply of P/N

& L/K Type water pumps. We only offer the high output water

pump as we see no benefit in simply fitting the alternative standard

three paddle type. Click

here or click image to visit our website for more information.

Finally,

we have replenished our supply of P/N

& L/K Type water pumps. We only offer the high output water

pump as we see no benefit in simply fitting the alternative standard

three paddle type. Click

here or click image to visit our website for more information.

More MMM viewing and reading material ...

We

are always surfing YouTube

for MMM clips and have found

some more to add to our current listings on the website. These will be

added shortly. The current clips

are

categorised by MG model and they can be found through our Links

web page or click here or on the image to go straight to our

Directory.

We

are always surfing YouTube

for MMM clips and have found

some more to add to our current listings on the website. These will be

added shortly. The current clips

are

categorised by MG model and they can be found through our Links

web page or click here or on the image to go straight to our

Directory.

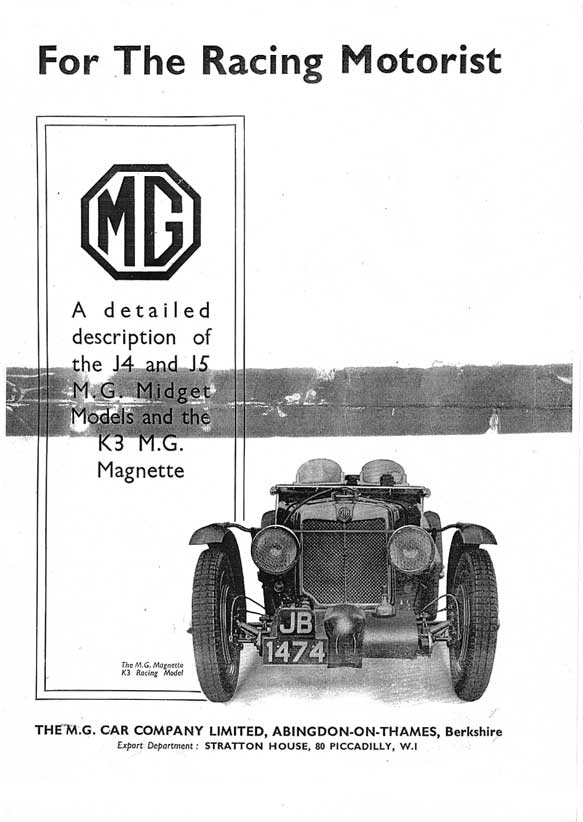

The MG

J5

- Members of the MMM Forum may have seen the reference made a

couple of months back to a rare original J4/J5/K3 factory sales

brochure which was being offered for sale on Ebay by Bob Holmes. He

very kindly agreed to forward a copy and we now have

pleasure in sharing it with you via our Links

web page. A very interesting factory publication even if the J5 was

possibly a

rather obsolete and generally pointless idea in the first place!

The MG

J5

- Members of the MMM Forum may have seen the reference made a

couple of months back to a rare original J4/J5/K3 factory sales

brochure which was being offered for sale on Ebay by Bob Holmes. He

very kindly agreed to forward a copy and we now have

pleasure in sharing it with you via our Links

web page. A very interesting factory publication even if the J5 was

possibly a

rather obsolete and generally pointless idea in the first place!

We have also received a new and very interesting MG story from Roy and Pauline Swallow about possibly one of the longest MMM restorations in history! We have added this to our website section 'MG Stories' featured on the Links web page, where fellow enthusiasts can submit their own MG tales or click here to go direct to their story.

We are looking for more MG stories to include in our next Newsletter. These generate great feedback from enthusiasts who can often generally relate to many of the tales involving our cars, so please share your experiences with readers as they are hungry for more...

Another year, another natter, and a few more beers ...

Following

on from our previous presentation in 2011, we

were invited back for

a second time in November 2012 to the

local MG Car Club 24/39 MMM Group Natter at Sicklinghall near Wetherby,

North Yorkshire.

Following

on from our previous presentation in 2011, we

were invited back for

a second time in November 2012 to the

local MG Car Club 24/39 MMM Group Natter at Sicklinghall near Wetherby,

North Yorkshire.

We brought along even more props and patterns including heavy sand cores and moulding boxes for the P type manifold, raw castings, another resin pouring demonstration and once again shared a few more manufacturing techniques and trade secrets. We had not expected such a large turnout and the room was full to capacity. We also had good representation from the VSCC community and some people had traveled up to 80 miles for the event. A thoroughly enjoyable night was had by all thanks to the excellent attendance and of course, equally excellent beer.

The MGCC Yorkshire 24/39 Group meet every two months and welcomes all new MMM members to this informal friendly gathering.

And finally ...

We are working on some further new projects and we always continue to welcome suggestions. In fact, all the new products announced in this newsletter have been initiated through your suggestions. We are also particularly interested in new leads on part sources and we would be pleased to hear from you.

With the new premises we are hoping that we can at last start work on our F2 project this year and we will be sharing our restoration progress in future newsletters.

On more general good housekeeping matters, we continue to strive to reply to a majority of emails quickly, day or night and try to help out whenever we can. Sometimes emails are lost in cyberspace or are returned as blocked by spam filters. Please email again if you do not receive a reply within 24 hours and add our email address to your list of ‘allowed’ addresses.

Please keep your photographs, articles and ideas coming and feel free to email Visitor's Gallery update photographs when projects have progressed.

We wish all fellow MG enthusiasts best wishes for a year full of happy MG motoring

With best wishes

Rich & Jill

If you do not wish to receive

another

newsletter from us then please

click

here to

unsubscribe

from further newsletters