Vintage MG Parts - Parts Site for the MMM Enthusiast

Rocker Shafts - C, D, J , P, L, N, K

(click on image to enlarge, click again to close)

"As always, absolutely perfect in every way. What a difference from the old ones, very nice material and the machining is great, the fit with the bushes is also as it should be."

(Customer feedback)

Vintage MG Parts are now able to offer customers rocker shafts of exceptional high grade material specification and these are available to enthusiasts using our special VMGP rocker finger bushes. Everything is made here in North Yorkshire and is exclusive to VMGP. We have improved the standard MMM arrangement and you may wish to read on for more details.

Why Fit VMGP Rocker Shafts?

We use BS 1407 Silver Steel which is centreless ground, gun drilled and case hardened for us. This tubing is to the original MG factory gauge. We then jig drill and counter bore all tubing inhouse.

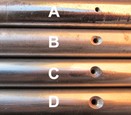

The photo below shows four shafts with comparisons on the delivery hole profiles:

(click image to enlarge, click again to close)

A |

- |

a standard factory M Type tube which also appeared on early J Types |

B |

- |

a typical repro shaft adopting shallow rough bore countersinking, very similar to factory P and N shafts |

C |

- |

VMGP shaft incorporating a deep milled hemispherical cup, very similar to the original L and K factory shafts |

D |

- |

an original K Type shaft showing a deep milled hemispherical cup around the delivery hole |

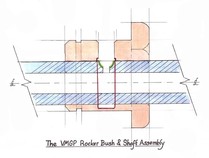

Our chosen diameter for the milled cup perfectly matches up with the oil delivery hole in the bush. This feature is highlighted with a green outline in the image below. There seemed to be no obvious benefit in enlarging to the full K /L size cup.

(click image to enlarge, click again to close)

We have noted that no parts reproduction company has reproduced rocker shafts for the K and L models in terms of the correct relative delivery hole positions. The spacings of the lobes on the standard N camshaft are marginally different to the L & K camshafts, as were the oil delivery hole drillings on the shafts but until now, enthusiasts have had to make do with what is available, i.e. N Type shafts. We have the correct jigs to supply. However, if using our original L / K shafts then check the relative cam lobe distances first on any new supply of camshafts as there may be some manufacturing complacency in using N Type lobe spacings. This is something we have not been able to check. It is best to have oil delivery holes and cam lobes perfectly aligned. Enthusiasts now have the choice in using the correct shafts for the correct standard factory cam.

All shafts are completely rodded through to debur, secondary drilled and re-inspected ready for immediate use.

We have jigged up for most models and we make these to order.

We also supply rocker finger bushes when in stock, rocker shaft intermediate support castings plus head gaskets.

Price--£POA pair--4 cylinder

Price--£POA pair--6 cylinder

(please state model when ordering)