Vintage MG Parts - Parts Site for the MMM Enthusiast

Rocker Finger Bushes & Circlips - C, D, J , P, L, N, K

(click on image to enlarge, click again to close)

Why VMGP Rocker Finger Bushes?

These bushes are precision CNC machined from a high quality brass alloy and incorporate improvements over the original factory bush as well as many reproduction bushes which have been manufactured since. As usual when making new parts, we have thoroughly researched this project and our bushes are now fitted in engines all over the world

The Bore

Our bushes have been CNC machine reamed (as opposed to rough bored, see photo below right marked "I" and "II") to circa 1/1000th inch over size for the rocker shaft bore to provide a perfect tolerance between the bush and the shaft when the rocker finger pinch bolt is tightened up. The bush will always marginally crimp up on the shaft and dependant on how much you torque up, you can hand ream after fitting if you so wish to re-check your tolerance fit. Reaming will reduce any shallow oil grove within the bush further, something to consider....

The Internal Oil Groove

We have increased the size of the oil groove in terms of depth and width. Good oil circulation is essential for our engines and whilst oil flow delivery rate is regulated by the oil delivery hole in the shaft (which remains as standard on our shafts), we have allowed more capacity in the groove itself for good circulation. Here are some comparison statistics on groove width, depth and volumetric capacity:

Width |

Depth |

Capacity |

|

Original factory (used) |

3.00 |

0.65 |

58.25 |

Common repro (new) |

3.00 |

--0.35 * |

31.50 |

VMGP (new) |

3.85 |

0.90 |

103.50 |

-------* before reaming

In the photo below centre right, you will appreciate why we wish to increase as oppose to reduce circulation capacity. The VMGP bush is marked "I" with a typical modern repro bush marked "II" where the comparisons are visually apparent. Also note our bore finish. The photo below left also details our improvements.

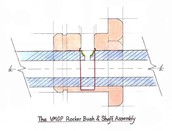

The scale drawing in the photo below centre shows the larger oil groove outlined in red. Note the green outline cup profile on the shaft (see also rocker shafts).

---

--- ---

---

(click on image to enlarge, click again to close)

General Machining and Choice of Material

In one of our engines, we have previously used stock item reproduction dural / aluminium alternatives. It is worth noting that whilst these continue to be retailed at a higher price than the brass alternative, the general opinion is that there is no real benefit to be offered apart from a nominal reciprocating weight loss. They have however, attracted adverse commentary over the years in that they do not retain the strength quality compared to the brass alloy alternative as they can readily 'crimp' onto the rocker shaft if the finger is marginally overtightened. This then creates excessive wear to the bush, fingers and cam. We recommend sticking to the original brass alloy type material.

Our bushes are suitable for J, P, L, N and K Types. The M, D and F Types as well as OHC Morris Minors used an early style rocker finger which is no longer available. However, the later style rocker fingers are widely available from a couple of sources and our bushes complement such components.

Our machining finishes are different to those undertaken on other modern bushes which are visually apparent to include the precision finish smooth internal bore, radii corners to all bore profiles (no burring), a deep oil groove and no fine machining chatter to the hex face.

We also manufacture high grade Chrome Moly rocker shafts to incorporate milled cups within the oil delivery holes, similar to original factory L/K shafts.

Price £8.00 each bushes

Price £0.28 each circlips (our own size)